Some background:

When we first looked into a cooling solution for iPads, the focus was first the cooling approach (which we decided on using fans), followed by deciding what other features will make it more usable. The idea of a "cooling case" was attractive as it provided some form of protection to the iPad while having cooling integrated within.

As we developed a few prototypes, we realised that since every iPad model has a slightly different dimension, we might need to create multiple toolings (for injection moulding) if we wanted to cater to the different iPad models. This means a huge startup cost with potentially huge wastage if the demand isn't there.

Thankfully, we were able to arrive at a design solution with suitable technologies and materials that mitigates the huge startup cost. It is a combination of modular design and additive manufacturing.

Modular design:

We designed the cooling case with 2 modules:

1) The iPad Sleeve

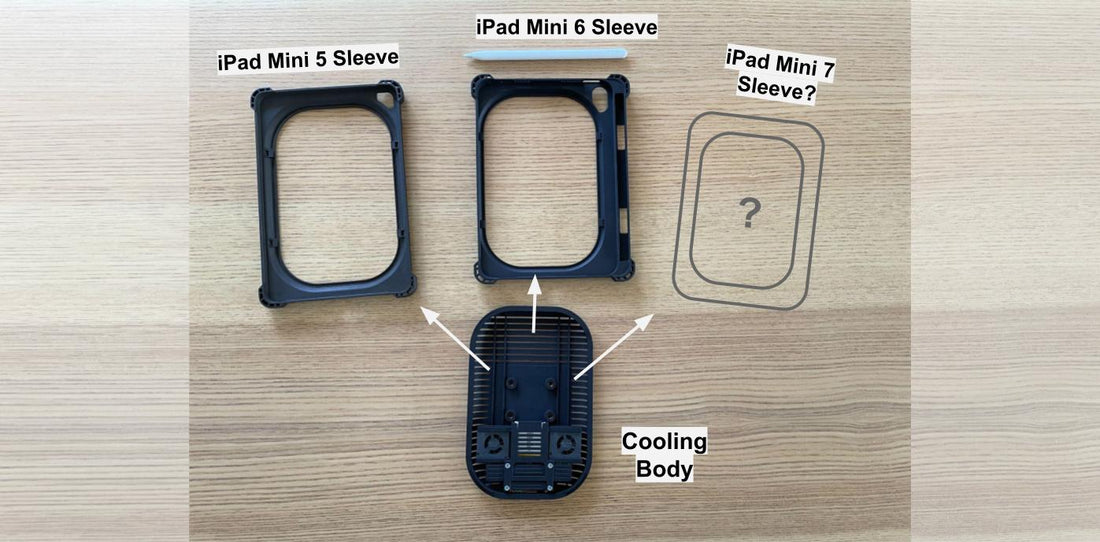

The iPad Sleeve with a "universal opening" that fits a specific iPad model (for e.g. the iPad Mini 6 Sleeve as seen below).

2) The Cooling Body

The Cooling Body houses the cooling fans and fits into the "universal opening" on the iPad Sleeve.

This makes the Cooling Body a universal part/module that fits any Sleeve with the "universal opening". Below is an example of the Cooling Body fitted on an iPad Mini 5 Sleeve and being swapped to an iPad Mini 6 Sleeve.

This means that when Apple releases the next iPad Mini, we would be able to design a new iPad Sleeve that fits the newer one. It will have the "universal opening" so it would fit the same Cooling Body.

So if someone already has the iPad Mini 5 cooling case or is getting the iPad Mini 6 cooling case, they can retain the Cooling Body for the next iPad Mini 7 Sleeve.

Where does additive manufacturing come in?

Additive manufacturing or 3D printing allows us to include design features that would be tricky to produce using traditional manufacturing methods. In this case, it is the attachment clips on the iPad Sleeve that secures the Cooling Body.

As mentioned in our recent post, amongst other advantages, additive manufacturing also allows us to produce the cases in small batches. While technologies such as Selective Laser Sintering, Stereolithography and Multi-Jet Fusion delivers high quality and precise parts that are suitable for our application.

If you would like to find out more, do subscribe to updates below or leave a comment if you have any questions about our design.